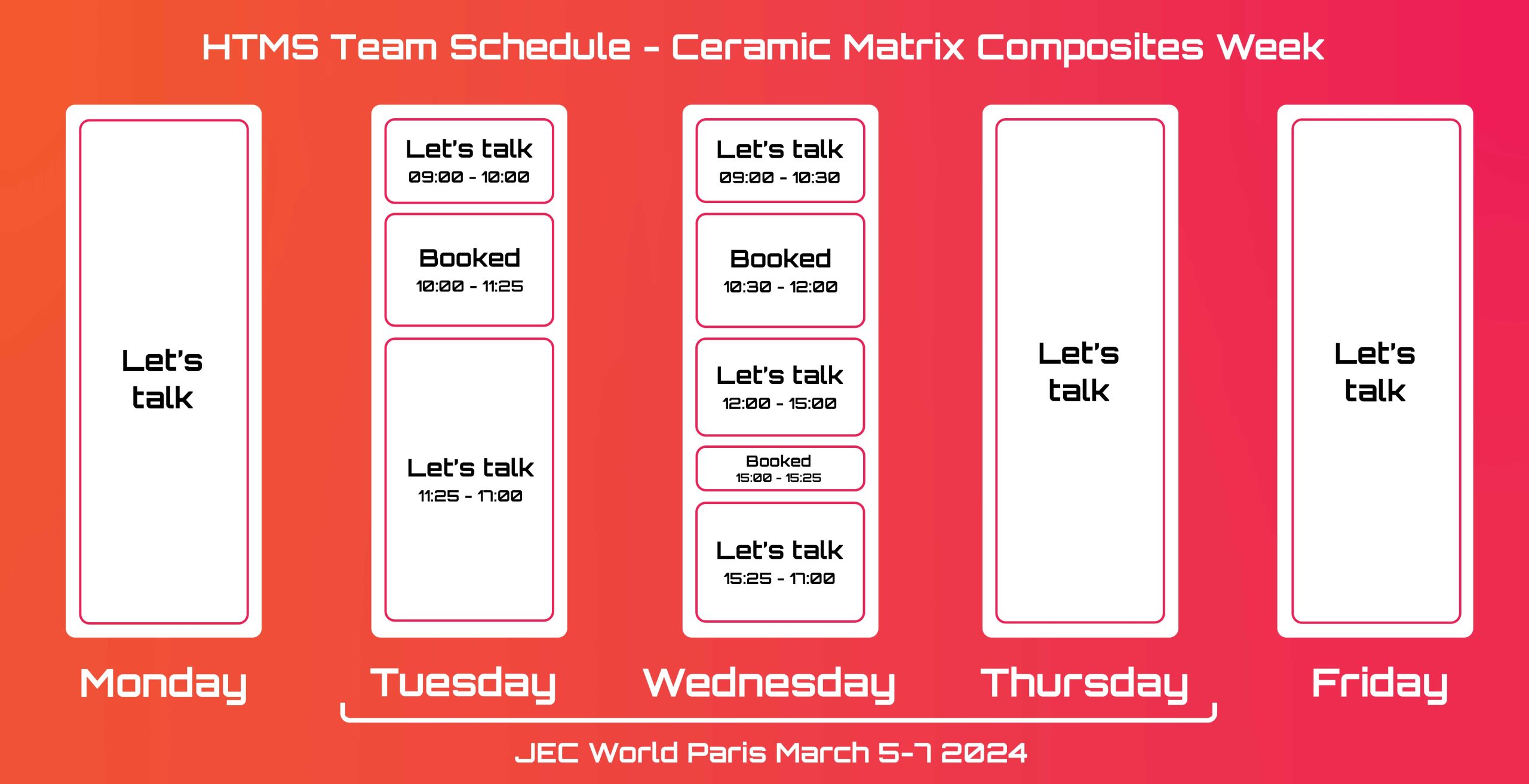

Welcome to Ceramic Matrix Composites week

with HTMS – Monday 4th – Friday 8th March 2024

Find out more about how we are enhancing the performance to cost ratio of thermal heat shielding using Ceramic Matrix Composite materials…

Meet the team online during the week or in-person at JEC Paris from 5th – 7th

where they will also be presenting.

Here is the availability of our team during the week:

Contact us, or book a meeting!

Download this handy information sheet now

What we do

ThermaLite

Thermal Shield

Introducing our innovative and affordable CMC system that delivers high-temperature performance tailormade for heat shield applications, spanning numerous sectors. Engineered for minimal mechanical loading, ThermaLite provides reliable and long-lasting even in the most extreme thermal conditions.

KappaCera

High-Temperature Low Dielectric Composite

HTMS has developed a novel CMC material that possesses a low dielectric constant even in high-temperature environments. This is the result of integrating advanced fibers into our state-of-the-art matrix system and optimising the chemistry within the entire system.

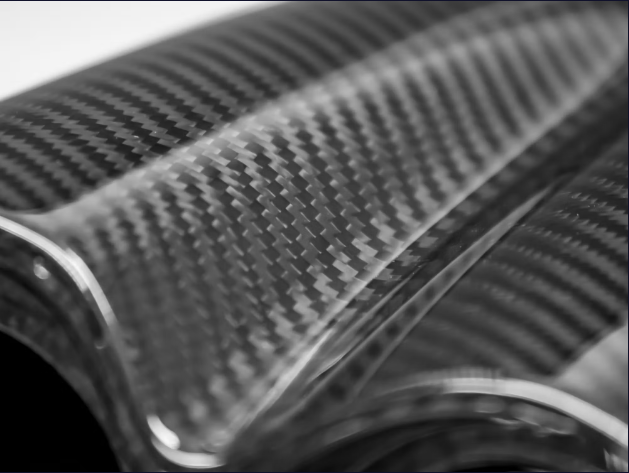

CarboniteX

Next Gen Composite

HTMS’s exploratory approach involves integrating high-strength Carbon fibres into our advanced matrix system, which expands the operational limits of Carbon-fibre based systems far beyond their current temperature capabilities.

IgniShield

Low Density Thermal Protection

IgniShield is a step change in the capability of thermal protection. This CMC is made by impregnating woven Basalt fibers with HTMS’s proprietary matrix. This solution is designed to excel in fire, smoke, and toxicity applications spanning sectors such as automotive, aerospace, and energy.

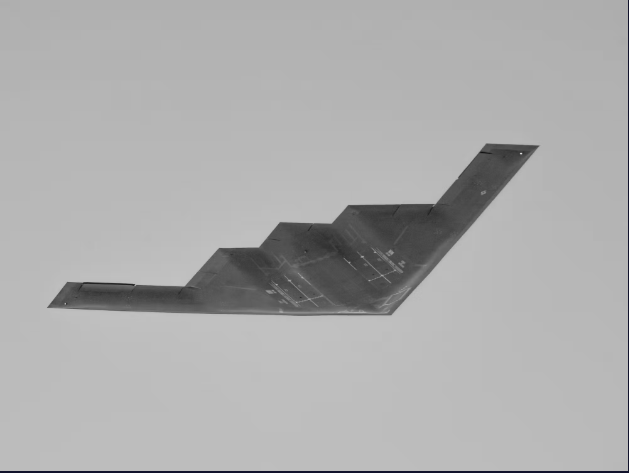

PhantomWeave

Multi-functional High Temperature Composite

HTMS’s newly developed CMC system is designed to meet the complex requirements of the defence sector. Combining low observable characteristics and high-temperature endurance, PhantomWeave is a generation after next CMC material.

ThermaLite

Thermal Shield

Introducing our innovative and affordable CMC system that delivers high-temperature performance tailormade for heat shield applications, spanning numerous sectors. Engineered for minimal mechanical loading, ThermaLite provides reliable and long-lasting even in the most extreme thermal conditions.

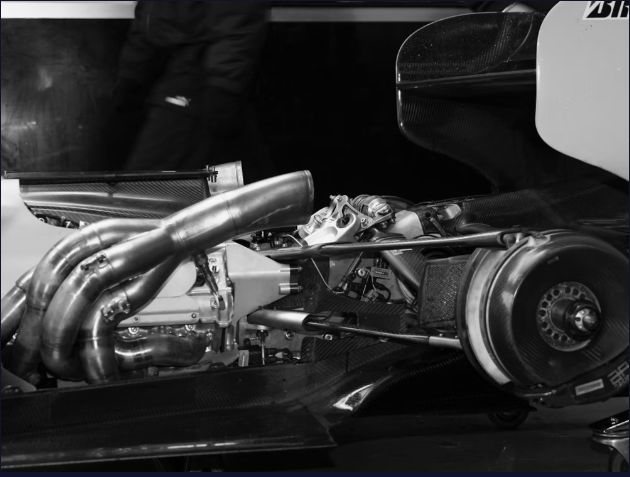

IgniShield

Low Density Thermal Protection

IgniShield is a step change in the

capability of thermal protection. This CMC is made by impregnating woven Basalt fibers with HTMS’s proprietary matrix. This solution is designed to excel in fire, smoke, and toxicity applications spanning sectors such as automotive, aerospace, and energy.

KappaCera

High-Temperature Low Dielectric Composite

HTMS has developed a novel CMC

material that possesses a low

dielectric constant even in high-

temperature environments. This is the result of integrating advanced fibers into our state-of-the-art matrix system and optimising the chemistry within the entire system.

PhantomWeave

Multi-functional High Temperature Composite

HTMS’s newly developed CMC system is designed to meet the complex requirements of the defence sector. Combining low observable characteristics and high-temperature endurance, PhantomWeave is a generation after next CMC material.

CarboniteX

Next Gen Composite

HTMS’s exploratory approach involves integrating high-strength Carbon fibres into our advanced matrix system, which expands the operational limits of Carbon-fibre based systems far beyond their current temperature capabilities.

Watch our welcome video to learn more

Sign-up now to receive more information or request a meeting to discuss our new technology, partnership for product development, production options, application examples, performance statistics, technical collaborations, academic research or investment opportunities.

FAQs

When was HTMS Founded?

High Temperature Material Systems Limited (HTMS) was founded in 2021. The company is partnered with the National Composites Centre in Bristol UK.

Who is behind HTMS technology?

Dr. Danilo Di Salvo, who holds a EngD in Aerospace Materials and worked on developing Ceramic Matrix Composites, and Dr. Richard Grainger who holds a PhD in Aerospace Composites and spearheaded the development of advanced composites manufacturing technologies for aerospace and automotive sectors at the Advanced Manufacturing Research Centre (AMRC) form the main technical driving force behind HTMS and its materials technologies.

What is a Ceramic Matrix Composite (CMC)?

High performance ceramics in this context are used for heat shielding. The use of fibres drastically increases the toughness of the Ceramic Matrix Composite (CMC) material when compared to monolithic ceramic structures.

How are HTMS CMSs different to what is on the market already?

Like most things in modern-day technology, research and development combined with new ideas and extensive testing leads to innovation in materials science that moves us forward in terms of available solutions. The HTMS team brings together a wealth of all these attributes in order to offer new Ceramic Matrix Composite solutions that are lighter, and retain their strength at high temperatures, while being less costly to develop and manufacture than incumbent material systems.

What are the main advantages of the HTMS chemistry?

The main advantages are more flexible application propositions, a much wider scope for performance specific solutions, so matching composite performance with individual application demands for shape, strength, heat shielding performance and reduced cost of production. We can match the performance of more traditional materials with a typically lighter, thinner wall solution – that costs less to develop and manufacture.

How much effect does lower temperature manufacture have on cost?

Lower sintering temperatures used during manufacture have a significant effect on the overall production cost and carbon footprint of HTMS designed CMC materials. So much so that it has opened up a huge number of new application industries and use cases that were previously economically unviable.

Are complex structures made from CMC possible?

Yes, HTMS materials can be used to make tiles, covers, tubes and many other complex shaped structures. A lower sintering temperature used for HTMS CMCs also allows for larger objects to be manufactured more easily and less energy intensely than previous generation high performance ceramics.

Can you coat other substrates?

The innovate nature of HTMS low-temperature ceramic chemistry does allow it to be bonded to other substrates, although its performance is optimised when combined with application specific HTMS CMC options.

What industries are using CMCs?

The main use cases for CMCs have traditionally been in high-value engineering projects such as space / aerospace / propulsion. The increased performance to cost ratio of the latest HTMS products however is opening-up huge areas of cost-effective application in automotive, power, transport and general industrial engineering involving high temperatures.